In guitar effects pedals, foot switches appear simple. You step on them, the effect turns on or off, and an LED indicator tells you what just happened. However, beneath its casing, this switch does something much more interesting. It determines the direction of the signal, which circuits are connected, and which remain isolated.

From a circuit perspective, a foot switch is like a traffic controller at an intersection. One path sends the signal directly from the input to the output. Another path routes the signal to the effects circuitry. A third path might power the indicator lights. The quality of this signal routing directly affects tone, noise, reliability, and the pedal’s performance on a crowded effects board.

This is why the debate between 3PDT and DPDT foot switches remains crucial in modern guitar effects manufacturing. This choice isn’t just about tonal philosophy; it also affects mechanical lifespan, assembly consistency, and the pedal’s performance after thousands of uses on stage.

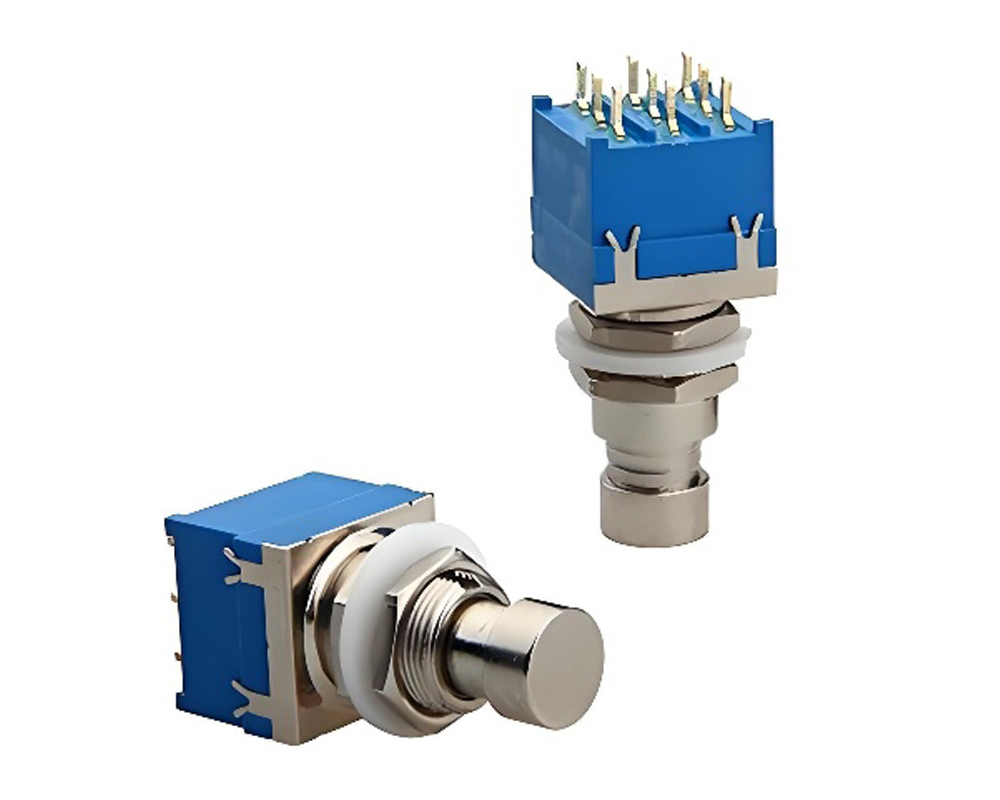

The 3PDT footswitch is one of the most commonly used mechanical switches in modern guitar effects pedal design, especially in effects pedals employing true bypass signal routing.

3PDT is an abbreviation for Three-Pole Double-Throw, a term describing the internal circuit connection control method of the switch.

- “Pole” refers to the independent circuit path that the switch can control.

- “Throw” refers to the number of positions each pole can connect to.

In a 3PDT switch, there are three independent poles, each of which can switch between two positions. This configuration allows multiple circuit paths to be changed simultaneously by pressing the switch once.

Internally, the 3PDT footswitch has nine terminals arranged in a 3×3 grid. When the switch is pressed, all three poles change state simultaneously, ensuring synchronized control of signal routing and auxiliary functions.

In contrast, the DPDT switch has only two poles, and therefore only six terminals. While the DPDT is sufficient for basic signal switching needs, it lacks the additional poles typically used for LED control in true bypass effects pedal designs.

It is this additional pole that makes the triple-pole double-throw foot switch a standard choice in effects manufacturing. It allows effects manufacturers to manage input routing, output routing, and visual status indication using a single mechanical component, without introducing active electronics into the bypass signal path.

Why 3PDT Became the Standard for True Bypass?

A classic true bypass guitar effects pedal must perform multiple functions simultaneously, without altering the audio signal when the effect is off.

In practice, a true bypass effects pedal requires:

- Routing the input signal to the effects circuitry or a direct output jack

- Completely isolating the effects circuitry when the pedal is off

- Controlling LED indicators to show whether the effect is active

A double-pole double-throw footswitch can handle basic audio routing, but it lacks an additional pole to control the LED. Therefore, early effects pedal designs using DPDT switches either omitted the LED or relied on additional electronics to drive it.

A triple-pole double-throw footswitch solves this limitation in a straightforward way. Two poles switch the audio signal between bypass and effects paths, while the third pole independently controls the LED’s on/off state.

This configuration enables a fully mechanical true bypass system, where the signal path is completely independent of active electronics when the effect is bypassed. This simplifies circuit design for circuit designers. For musicians, it provides a bypass tone that feels like a direct connection between the guitar and the next device in the signal chain. It is this balance between functional simplicity and predictable signal characteristics that makes the 3PDT foot switch the preferred solution for true bypass effects designs.

True Bypass vs Buffered: What the Switch Really Changes?

True Bypass: Direct and Unfiltered

In a true bypass design, the signal avoids all active electronics when the pedal is off. The guitar sees the next pedal or the amp directly, with no buffer in between.

This approach is often compared to opening a straight gate. When the gate is open, nothing touches the signal. When it is closed, the signal takes a detour through the effect.

True bypass works well in small pedalboards with short cable runs. It also appeals to players who want predictable interaction between guitar pickups and downstream gear.

Buffered Bypass: Controlled and Consistent

A buffered bypass pedal keeps the signal passing through an active buffer even when the effect is disengaged. This buffer stabilizes impedance and helps preserve high-frequency content over long cable runs.

Buffered designs usually rely on DPDT switches or electronic switching, because the LED and routing are handled by active circuitry instead of mechanical poles.

From a manufacturing standpoint, buffered switching can reduce mechanical stress on the foot switch. From a player’s perspective, it can improve consistency on large pedalboards.

The real takeaway is that the switch type supports the design philosophy, rather than defining tone on its own.

Durability Matters: Life Cycle and Stage Reality

Mechanical Life Cycle in Real Use

A foot switch is one of the most abused components in a pedal. It is pressed with boots, shoes, and sometimes full body weight. On tour, a switch may be actuated hundreds of times per night.

Mechanical switches are rated by life cycle, typically measured in tens or hundreds of thousands of operations. That number is not academic. A switch that feels fine in the workshop may fail early under stage conditions if the internal contacts or spring mechanism are poorly designed.

For manufacturers, inconsistent switch quality leads to warranty returns, brand damage, and assembly line headaches.

Soft Click vs Hard Click: Feel Is Not Just Preference

Foot switch “feel” is often described as soft click or hard click, but that tactile difference comes from internal construction.

Hard click switches usually have a stronger spring and a more pronounced mechanical latch. They provide clear feedback but can produce audible popping if the circuit is not carefully designed.

Soft click switches reduce actuation force and mechanical noise. They are often preferred for quieter switching and smoother user experience.

Bituo’s 3PDT switches are engineered to balance tactile feedback with controlled actuation force. For builders, this means predictable installation torque, consistent height, and reliable contact alignment across production batches.

Other Essential Hardware in Pedal Manufacturing

A foot switch never works alone. Several supporting components define how the pedal performs and how easy it is to manufacture at scale.

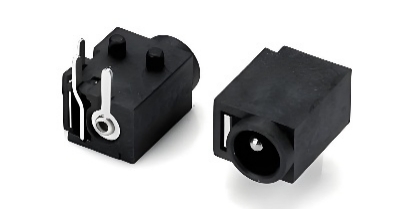

DC Power Jacks: The 2.1mm Standard

Most modern guitar pedals rely on 2.1mm center-negative DC power jacks. This format has become the industry default because it balances current capacity, mechanical strength, and compatibility with common power supplies.

From an engineering perspective, the power jack must handle repeated insertions, lateral stress from cables, and potential short circuits during plugging. Poorly plated contacts or loose tolerances often cause intermittent power issues that are difficult to diagnose after assembly.

Choosing OEM-grade DC jacks with consistent dimensions helps reduce enclosure fit issues and rework on the production line.

Battery Clips: Still Relevant for Vintage-Style Pedals

Although many players rely on pedalboard power supplies, battery clips remain relevant for certain designs.

Vintage-inspired pedals often include battery compartments for portability or period-correct design. A low-quality battery clip can introduce resistance, intermittent power loss, or mechanical failure when the enclosure is opened repeatedly.

For manufacturers, using standardized, strain-relieved battery clips reduces support issues while preserving compatibility with classic layouts.

Why OEM Quality Matters in Pedal Manufacturing?

Consistency Beats Individual Perfection

In prototyping, a single high-quality switch is enough. In production, consistency matters more than perfection.

OEM pedal builders depend on components that meet the same mechanical and electrical specifications across thousands of units. Variations in pin alignment, actuation force, or plating thickness slow down assembly and introduce unpredictable behavior in finished pedals.

Bituo focuses on specification control across batches, ensuring that foot switches, DC jacks, and related hardware behave the same way from the first unit to the last.

Bulk Procurement and Specification Control

For professional pedal parts sourcing, bulk procurement is not only about price. It is about:

- Stable supply

- Repeatable tolerances

- Clear documentation

- Predictable long-term availability

A component that disappears or changes specification mid-production can force redesigns, new testing cycles, and certification delays.

Having access to well-documented datasheets allows engineers and purchasing teams to align electrical design, mechanical layout, and quality control from the start.

Conclusion

In the competitive landscape of effects pedal manufacturing, a product’s field reliability hinges on its most frequently used components. For builders, utilizing high-performance hardware is a prerequisite for delivering professional-grade equipment that survives the rigors of the road. Selecting the appropriate foot switch, DC power jack, or battery clip is more than a technical specification; it is a commitment to the musician’s performance and the brand’s long-term reputation for durability.

At Bituo, we recognize that consistency is the foundation of an efficient production line. We prioritize stringent specification control and repeatable tolerances to provide OEM-grade solutions that streamline assembly and minimize warranty overhead.

Whether you are scaling a boutique operation or managing high-volume manufacturing, Bituo hardware ensures that every actuation on stage is as responsive and reliable as the first. By partnering with a supplier focused on precision and long-term availability, manufacturers can focus on what matters most: creating exceptional tone.