Many guitarists spend years pursuing a better tone. They replace pickups, upgrade amps, try new effects pedals, and constantly refine their playing techniques. Yet, they still encounter signal loss, commonly known as “tone loss.” While this problem is often attributed to the order of effects connections or cable length, the root cause is often poor-quality pedalboard components.

In a typical guitar effects pedal signal chain, every connection is crucial. The 1/4-inch headphone jack, DC power jack, and footswitch inside each effects pedal create dozens of physical contact points.

When these components are poorly made or wear out prematurely, signal attenuation is inevitable. Even with high-quality effects pedals and cables, poor-quality connectors will affect tone clarity, dynamic range, and reliability.

Understanding how high-quality jacks and switches affect signal integrity helps musicians make more informed choices, whether building their own effects pedals, assembling touring pedalboards, or maintaining existing equipment.

Maintaining Signal Integrity in the Guitar Pedal Signal Chain

How 1/4 Inch Phone Jacks Affect Conductivity?

The guitar pedal signal chain is fundamentally analog. Small changes in resistance, grounding quality, or contact pressure can influence high-frequency response and dynamic range. This is where the construction of a 1/4 inch phone jack becomes highly relevant.

Low-cost jacks often rely on thin metal alloys or inconsistent plating. Over time, oxidation and mechanical fatigue reduce conductivity at the contact points. This results in subtle but cumulative signal loss, especially noticeable when multiple pedals are chained together.

High-quality phone jacks use solid metal housings and carefully selected conductive materials. These materials provide more consistent electrical contact and reduce micro-resistance that can dull attack or soften high-end response. The result is a signal that remains closer to the original guitar output, even after passing through complex pedalboard setups.

Reducing Wear from Frequent Plugging and Unplugging

Pedals are not static devices. Cables are plugged in and removed repeatedly during rehearsals, live performances, and studio sessions. Each insertion places mechanical stress on the jack’s internal contacts.

Poorly designed jacks lose tension quickly, leading to loose connections that cause crackling, intermittent signal dropouts, or sudden volume changes. High-quality jacks are engineered with spring structures that maintain contact pressure over long usage cycles. This design minimizes wear and preserves stable signal transfer even after thousands of plug-in cycles.

Powering the Pedal: Why DC Jacks Matter?

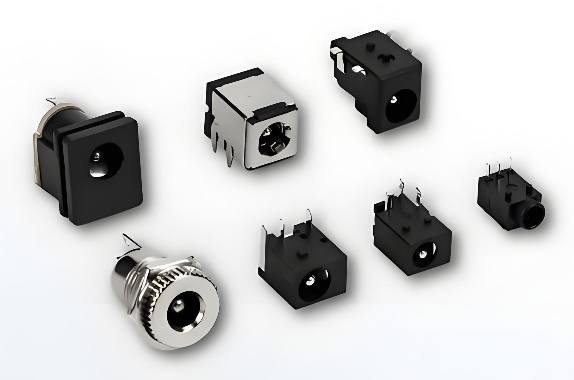

Signal integrity is not only about audio paths—it also depends on stable power delivery. Inside every pedalboard power supply setup, DC jacks serve as the connection between the power source and each effect unit.

Low-quality DC jacks can loosen over time or develop poor internal contact. In live environments, this can lead to momentary power loss when the pedalboard is bumped or when cables shift slightly. Even brief interruptions may cause digital pedals to reboot or analog circuits to behave unpredictably.

High-quality DC jacks are designed with secure contact geometry and reinforced housings. This helps maintain steady current flow under vibration and movement, which is common on stage. For musicians, this means fewer surprises during performances and smoother operation throughout a set.

The Role of Insulation and Dust Protection

Pedalboards are exposed to dust, humidity, and temperature changes. Without proper insulation, DC jacks can accumulate debris or moisture, increasing resistance and raising the risk of electrical noise.

Well-designed DC jacks incorporate insulation materials that isolate power contacts from the enclosure and surrounding components. Dust-resistant designs further protect the internal structure, improving long-term reliability for both touring musicians and home studio users.

Customization Trends in Modern Pedal Design

Visual Customization: Switches, Knobs, and User Identity

Beyond sound quality, modern guitar effects pedals are increasingly becoming a visual extension of a player’s personality. Today, manufacturers and brands offer colored footswitches, custom interfaces, and knobs made from a variety of materials.

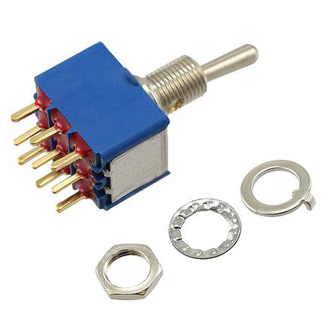

High-quality switches go beyond just appearance. Their internal structure affects tactile response and mechanical lifespan. A well-constructed footswitch provides stable actuation force and reduces contact bounce, which is especially important for true bypass designs and relay-based switching systems.

Mini Pedals and the Demand for Compact Components

As pedalboards become more compact, mini pedals have gained widespread popularity. These smaller enclosures place higher demands on component design. Standard-size jacks and switches may not fit, and crowded layouts increase the risk of mechanical interference.

Miniaturized pedal components must maintain electrical stability while occupying less space. This requires precise manufacturing tolerances and thoughtful internal layout. High-quality compact jacks and switches help builders create smaller pedals without introducing noise or durability issues.

For players, this trend allows more effects on a single board while maintaining signal clarity.

Bituo’s Role in the Music Industry

Bituo supports the global music equipment ecosystem by supplying reliable pedal components to effects pedal brands, boutique builders, and DIY workshops. Rather than focusing on finished consumer products, Bituo concentrates on the underlying hardware that determines long-term performance.

By providing consistent 1/4 inch phone jacks, DC jacks, footswitches, and related components, Bituo enables builders to maintain sound consistency across production runs. This is especially valuable for small and mid-sized pedal brands that rely on component stability to protect their reputation.

Practical Checklist: Evaluating Your Pedalboard Components

Before investing in new pedals or rearranging your signal chain, it can be helpful to review the physical components already in use. The following checklist can help identify potential weak points:

- Do any input or output jacks feel loose when cables are connected?

- Is there crackling or signal drop when cables are moved?

- Do pedals lose power when the board is lightly bumped?

- Are DC jacks firmly seated with no visible movement?

- Do footswitches actuate consistently without sticking or double-triggering?

- Are connectors visibly oxidized or discolored?

If several of these issues are present, upgrading internal components may improve overall signal clarity more effectively than changing pedals or cables.

Conclusion

Signal loss is rarely a sudden disaster; it’s caused by the cumulative effect of various inefficient links in the signal chain. Over time, oxidized jacks, fatigued mechanical switches, and unstable DC connections silently erode your tone and reliability.

Maintaining signal integrity hinges on using high-quality 1/4-inch headphone jacks and precision-designed switches. As effects boards become increasingly compact and complex, hardware quality has become a critical factor in performance.

Whether you’re a touring professional or a small effects manufacturer, investing in the hardware beneath the cabinet ensures your tone remains consistently sensitive and reliable.