Aluminum process enclosures have become an essential part of modern technology, providing protection and safety for electronic components in various industries. These enclosures are popular due to their unique combination of strength, durability, lightweight nature, and versatility.

Whether used in telecommunications, industrial controls, or consumer electronics, aluminum enclosures offer a wide range of benefits that make them the go-to choice for housing sensitive devices.

In this blog, we will explore why aluminum process enclosures are so widely used and how they benefit industries that rely on protective casings for their electronic components.

The Advantages of Aluminum Enclosures

Aluminum enclosures stand out in many industries due to several distinct advantages that make them both practical and cost-effective.

Durability and Strength

Aluminum is inherently a strong material, capable of withstanding harsh environmental conditions. While being lightweight, it offers substantial protection against physical damage, impacts, and stresses that might otherwise harm delicate electronic components.

The robustness of aluminum ensures that the enclosed equipment remains safe and secure, even in high-demand or hazardous environments. Additionally, aluminum enclosures can endure physical abuse such as vibration, ensuring the longevity of the equipment housed within.

Lightweight Nature

One of the primary reasons why aluminum enclosures are so popular is their lightweight design. The low weight of aluminum compared to other metals, like steel, reduces transportation costs and makes handling easier.

In applications where weight is critical, such as in aerospace or mobile devices, the lightweight nature of aluminum makes it an ideal material for enclosures. Manufacturers can build larger enclosures or housings without significantly increasing the overall weight of the unit, which is crucial for applications requiring portability or energy efficiency.

Corrosion Resistance

Aluminum is naturally resistant to corrosion, thanks to its oxide layer that forms when it comes into contact with air. This oxide layer acts as a protective barrier, preventing further oxidation and shielding the material from moisture, chemicals, and other corrosive elements. This makes aluminum enclosures highly suitable for outdoor applications, industrial settings, or environments that are exposed to moisture, salts, or other corrosive substances. The resistance to rust and corrosion ensures that the equipment remains protected for a longer period without the need for frequent maintenance or replacements.

Superior Thermal Conductivity

In applications where heat dissipation is a concern, aluminum enclosures offer excellent thermal conductivity. Heat tends to accumulate in electronic devices during operation, and managing this heat is essential to maintain optimal performance and prevent overheating.

Aluminum’s ability to effectively dissipate heat ensures that the enclosed components stay within safe operating temperatures, enhancing their lifespan and reliability. This makes aluminum a popular choice in industries such as telecommunications, automotive, and medical devices, where maintaining stable temperatures is critical to the performance of sensitive equipment.

Electromagnetic Interference (EMI) Shielding

Electromagnetic interference (EMI) is a significant concern in many industries, particularly in fields like telecommunications, medical equipment, and consumer electronics. EMI can disrupt the performance of sensitive electronic components, causing malfunction or degradation in functionality. Aluminum, being a conductive material, acts as a natural shield against EMI and radio frequency interference (RFI).

Enclosures made of aluminum provide effective protection against external electromagnetic fields, ensuring that the enclosed devices continue to operate efficiently without interference from their surroundings.

Applications of Aluminum Process Enclosures

Due to their unique properties, aluminum enclosures are used in a wide range of industries and applications, where they provide not only protection but also functionality and design flexibility. Some of the most common applications include:

Industrial and Automation Controls

Aluminum enclosures are widely used in industrial settings to house electrical components such as control panels, sensors, and other automation devices. The robustness of aluminum ensures that these components are protected from dust, moisture, and physical damage, while also allowing heat dissipation to prevent overheating. These enclosures often need to meet strict safety standards, such as IP ratings, to ensure that they are adequately sealed and protected from the environment.

Telecommunications and Networking

In telecommunications, aluminum enclosures are used to house sensitive equipment such as routers, switches, and signal processors. The need for electromagnetic shielding to protect against interference makes aluminum the ideal material. Furthermore, the material’s resistance to environmental stress, such as humidity and corrosion, is essential for devices that are exposed to outdoor conditions, especially in harsh climates.

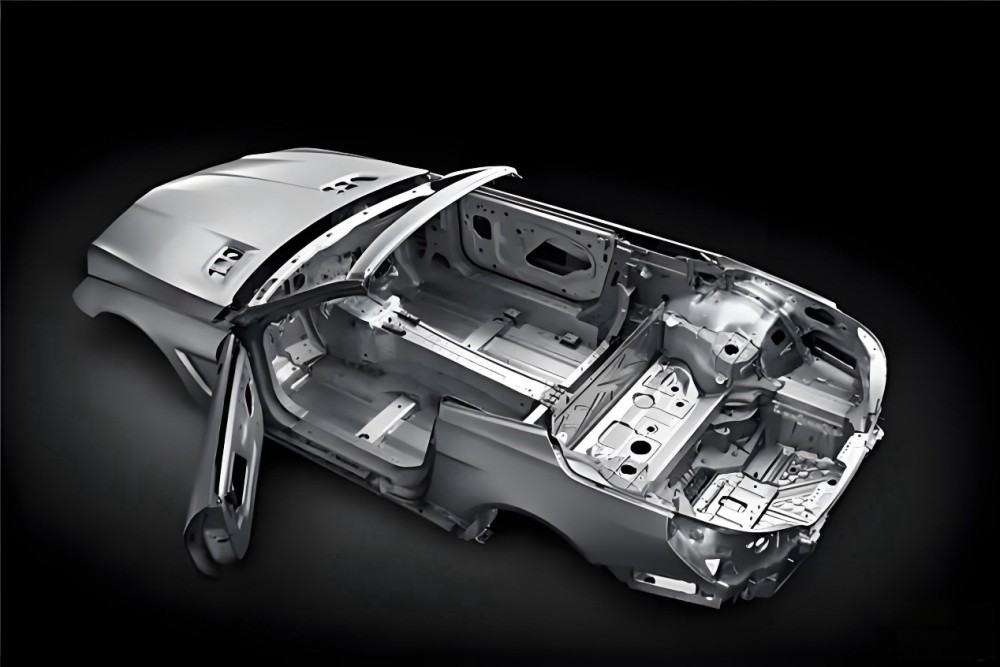

Aerospace and Automotive

Aluminum is highly valued in both the aerospace and automotive industries, primarily due to its lightweight nature and durability. In aerospace, where weight reduction is crucial for fuel efficiency and performance, aluminum enclosures protect electronic systems used in aircraft while keeping the overall weight of the equipment to a minimum. Similarly, in automotive applications, aluminum enclosures are used to protect critical electronic systems and sensors, providing durability in environments with high vibration and temperature extremes.

Medical Equipment

Aluminum enclosures are frequently used in medical devices such as diagnostic machines, portable medical devices, and patient monitoring systems. These enclosures provide a durable, lightweight solution while ensuring that the internal electronics remain safe from external damage. Furthermore, the ability of aluminum to dissipate heat is especially important for preventing overheating in sensitive medical equipment that operates continuously or in critical situations.

Consumer Electronics

Many consumer electronics, including audio systems, gaming consoles, and laptops, rely on aluminum enclosures for both functional and aesthetic reasons. Aluminum offers an attractive finish that is resistant to wear and tear, maintaining the appearance of the device over time. Its ability to dissipate heat and provide electromagnetic shielding also enhances the performance of consumer devices, ensuring they operate at optimal temperatures while remaining resistant to interference.

Factors to Consider When Choosing Aluminum Enclosures

While aluminum enclosures offer numerous benefits, it is essential to consider a few key factors to ensure you select the right enclosure for your specific application.

Alloy Type

The performance of an aluminum enclosure can vary depending on the alloy used. Different aluminum alloys offer different levels of strength, corrosion resistance, and formability.The choice of alloy can impact the enclosure’s overall durability and longevity, so it is essential to choose the right one based on the environment in which the enclosure will be used.

Surface Treatment and Finishing

Aluminum enclosures can undergo various surface treatments to enhance their appearance and functionality. Anodizing is a common process that increases the thickness of the oxide layer, improving corrosion resistance and providing a more durable finish.

Additionally, anodizing can be used to add color to the enclosure, which can be aesthetically pleasing or used for identification purposes. However, it’s important to consider how these treatments affect the overall dimensions and tolerances of the enclosure, especially if precise fitting is required for specific components.

Sealing and Gaskets

For applications that require protection from dust or moisture, the enclosure must be properly sealed. This can be achieved using gaskets or sealing mechanisms that prevent the ingress of contaminants. Ensuring that the aluminum enclosure has the necessary sealing features is vital for protecting sensitive electronics in environments that involve exposure to dust, moisture, or chemicals.

Compliance with Standards

Depending on the industry and application, it’s crucial to choose an aluminum enclosure that complies with relevant safety and performance standards. For example, IP (Ingress Protection) ratings specify the enclosure’s level of protection against dust and water, while UL certification ensures that the material meets safety requirements for electrical devices. Always verify that the enclosure meets the necessary standards before making a final selection.

Conclusion

Aluminum process enclosures have earned their popularity due to their combination of lightweight design, strength, corrosion resistance, and versatility. Whether used in industrial control systems, medical equipment, telecommunications, or consumer electronics, aluminum enclosures provide essential protection and enhanced performance.

Their ability to manage heat, shield against electromagnetic interference, and withstand harsh environments makes them an ideal choice for various applications. By understanding the benefits and considerations associated with aluminum enclosures, manufacturers can make informed decisions, ensuring that their equipment remains safe, reliable, and functional for years to come.